Фрезерный станок 5-осевой сухого обработки модель S 500 изготовитель компания PHILDENT

Фрезерный станок 5-осевой сухого обработки модель S 500 изготовитель компания PHILDENT

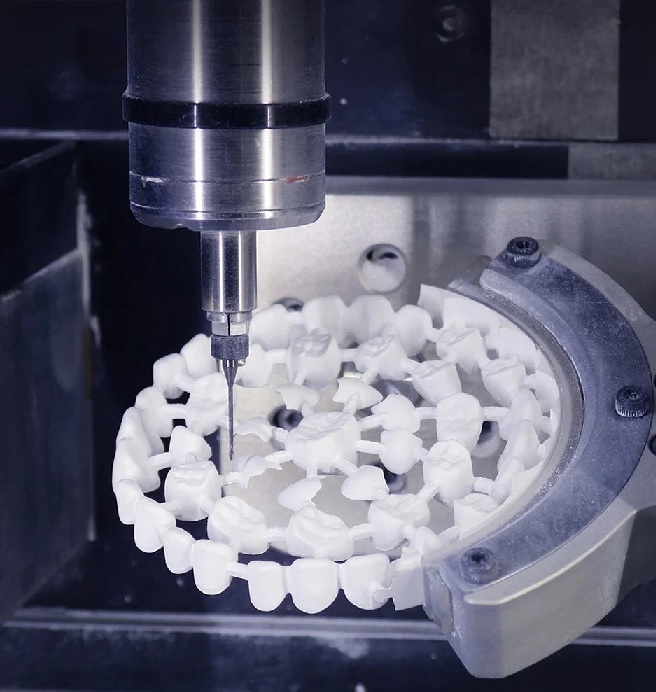

Фрезерный станок модель S 500 - это инновационный, современный, высокого качества, точный, производительный, надежный,скоростной фрезер, от известного китайского производителя компании PHILDENT. Пяти осевой фрезерный станок S 500, предназначенный для сухой обработки, быстро и точно фрезеровать различные виды материала: циркон, композитный материал, РММА, воск, и мягкий синтер-металл 98,5мм. Простое в использовании интеллектуальное меню, контроль процесса фрезерования и инструментов, комфорт и удобство в работе, обеспечивает высокий стабильный результат отфрезерованной работы.

Открытая система

Позволяет работать с новейшими различными материалами и CAD/CAM программным обеспечением

Автоматическая калибровка

Снижает трудозатраты, не требуя от оператора ручной калибровки, тем самым увеличивая эффективность производства, качество и безопасность продукции, обеспечивая мониторинг и отслеживаемость в реальном времени, что может принести лабораториям устойчивые конкретные преимущества.

Шпиндель с длительным сроком службы

Мы используем низковольтный и высоковольтный электрический шпиндель с низким тепловыделением что позволяет увеличить время работы.

Обеспечивает фрезерование под углом 90°

Это позволяет достичь лучшего эффекта фрезерования передних зубов и сократить время полировки, затрачиваемое лабораториями.

Высокая стабильность и точность

Цельнолитая конструкция позволяет создать устойчивую рабочую платформу для обеспечения точности и стабильности процесса. Такая конструкция относительно проста, что упрощает и повышает эффективность технического обслуживания и ремонта. Она может сохранять стабильные характеристики при длительной эксплуатации, сокращая время простоя и затраты на обслуживание.

Автоматическая замена инструмента

12-станционное устройство смены фрез

Работает- со стандартным набором фрез, с дополнительно адаптовоною фрезой 0,3мм для качественной и точной обработки фиссур и контактов.

Простота в создании сети

Оснащен сетевым интерфейсом для упрощения развертывания сети: Прибор может автоматически находить и идентифицировать ближайшие сетевые приборы, устанавливать соединение без сложной ручной настройки и обеспечивать пользователям удобное подключение к сети Wi-Fi и передачу данных.

Технические характеристики:

5-осевой

Сухое фрезерование - шпиндель выталкивает газ высокого давления для очистки и охлаждения во время фрезерования

Линейная ось - прецизионная шарико-винтовая пара, прецизионная направляющая точность повторения ±5μm, прецизионный ход давления, X/Y/Z: 176/134/100 мм

Ось вращения - прецизионный двигатель, прецизионный гармонический редуктор, точность повторения ±0,01° Ось А±32° Ось В ±360°

Система управления - встроенная FPGA высокоскоростной параллельной обработки команд, оснащенная операционной системой реального времени поддерживающая стандартные G-команды (RS274X) и расширенные команды. Встроенные преобразователи частоты для синхронных и асинхронных двигателей делают его более гибким и совместимым. Поддержка многих аналоговых и цифровых IО.

САМ - Поддержка Millbox, Hyperdent and WorcNc

Интерфейс данных - Интерфейс RJ45 Ethernet, само адаптивный 10/100М, необходимый для работы в сети

Шпиндель - высокочастотный, асинхронный, смена инструмента с помощью воздуха (не возвращается во время замены инструмента), воздушное уплотнение для предотвращения попадания посторонних предметов

Мощность - 900W (5S,Pmax),400W(S6),2500W (S1)

Скорость вращения - до 60,000 об/мин

Зажим цангового механизма - подходит для фрезерных боров диаметром хвостовика 4 мм, длиной 50 мм

Магазин инструментов - 12 инструментов, встроенный калибр

Компрессорный воздух - 4-8 бар (0,4-0,8 МПа), Чистота воздуха в соответствии с: ISO8573-1:2010, необходимо обустройство холодным осушителем.

Электропитание - 220V / 50-60HZ / 700W

Структура фрезера - цельнолитой алюминиевый корпус

Размер - Д / Ш / В 495*593*627*

Вес - 80 кг

+38 096-957-87-31

+38 096-957-87-31

+38 050-504-86-31

+38 050-504-86-31

+38 050-674-33-31

+38 050-674-33-31

+38 096-957-87-31

+38 096-957-87-31